How a Failed Dessert Startup Led to Industrial Energy Innovation in Southeast Asia

08/08/2025

From time to time, most of us would have thought of pivoting to something else, something new. And many of these times, we don’t do it. Is it really because of the fear of the unknown, or because we think we don’t have it in us to change? Well, Jeremy Tan’s pivot was radical: from B2C dessert technology to B2B industrial biomass solutions.

How did he do it?

Jeremy’s passion for entrepreneurship started growing when he went through National University of Singapore’s Overseas Colleges programme, exposing him to startup life and aspiring founders from all walks of life. It peaked during his corporate years at ExxonMobil and Singtel, where he traded corporate performance appraisals for the highs and lows of startup life.

SWIRLGO: The Nespresso for Desserts

While still working full-time, Jeremy began developing Swirl.GO—a hardware platform he describes as “democratising desserts through capsules, like how Nespresso did it for coffee.” The concept was deceptively simple: create a machine that could transform frozen capsules into perfect soft-serve desserts.

But simple concepts often hide complex execution. “There was a lot more technical depth needed to invent something that could really convert something frozen into soft serve,” Jeremy explains. The existing solutions in the market were inadequate—industrial soft-serve machines that cost $10,000, required extensive maintenance, and offered only single flavours.

Photo: Ravin Thiruchelvam/HungryGoWhere

Jeremy’s vision was different. His machine would be fast, hygienic, and capable of creating hundreds of flavours and form factors—smoothies, milkshakes, different textures—all from capsules. The technical innovation was significant enough to earn patents in Europe and Japan, and the company successfully raised and deployed its machines in restaurants, offices, and hotels. From the outside, Swirl.GO looked like a startup success story in the making.

The Hard Truth About Hardware

But beneath the surface, fundamental challenges were emerging. “We realised it was really hard to turn a profit,” Jeremy admits. “You had a great product, but it was really challenging to extend the lifetime value of every customer.”

Photo: Ravin Thiruchelvam/HungryGoWhere

The core issue was usage frequency. While coffee drinkers might consume 1-2 cups daily, ice cream consumption was around 3 times per week. And for restaurants, the machines became more of a novelty promotion rather than a consistent revenue generator.

By late 2023, after a series of revenue challenges and the inability to achieve sustainable unit economics, Swirl.GO ceased operations. “We ran out of money and figured there was really no point to push further.”

From Ice Cream to Biomass

Instead of taking time to recover from the setback, Jeremy swiftly enrolled into ENGIE Factory to identify and apply his learnings on a new problem worth solving. And soon enough, he discovered the solution to a pain point with perfect “hair on fire” characteristics: biomass pellets for industrial energy needs.

The “hair on fire” concept, borrowed from Y Combinator, became Jeremy’s core guiding principle this time. “You want to sell to customers with their hair on fire because they’ll want a product they can immediately use, even if it’s imperfect.”

The Philippines presented the perfect storm of such an urgent need. As one of the world’s most coal-dependent countries, with expensive imported coal and mounting pressure to transition to cleaner alternatives, industrial customers were literally burning money daily. “Every single percentage point on pricing means the difference in their P&L,” Jeremy notes.

Engineering Solutions for Real Problems

This is where Jeremy’s second startup, Vertas, emerged to address this critical gap by producing built-to-spec biomass pellets engineered specifically for industrial boilers. Unlike generic biomass alternatives, Vertas develops unique blends that work seamlessly with existing equipment—no modifications required.

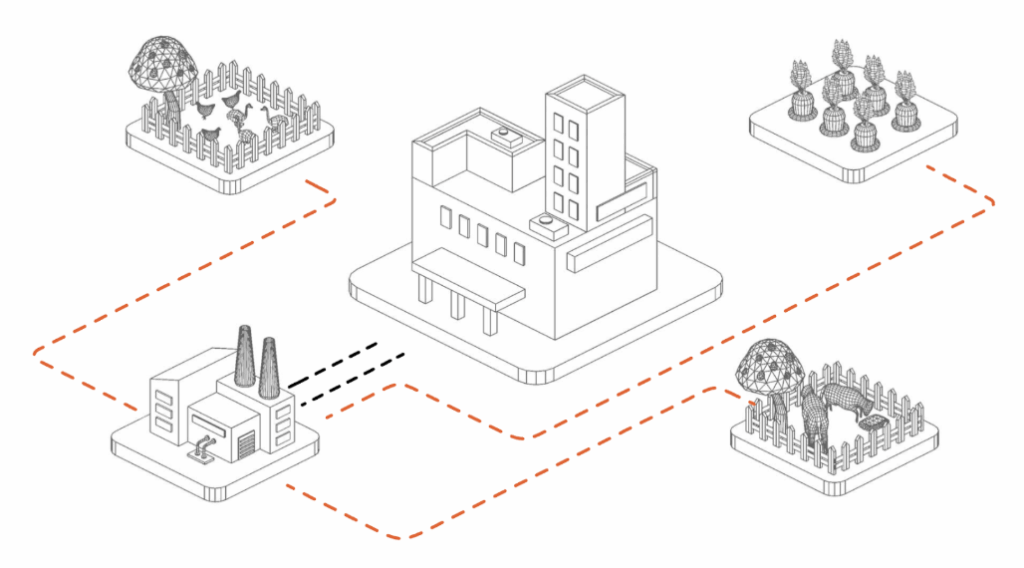

Vertas aggregated feedstocks through agriculture and livestock farms near client’s operations for cost efficiency and sustainability.

The proof is in the performance. Within five months of their partnership with KLT, a leading food processing company in the Philippines, the startup helped reduce their fuel costs by 17% while significantly lowering emissions at the same time.

Today, Vertas has secured three multinational clients, including Universal Robina. The team also has an extensive pipeline of potential clients, all in the Philippines. The company has successfully closed multiple funding rounds and is evaluating expansion across Southeast Asia, targeting markets with similar coal dependency and infrastructure needs.

Jeremy’s Entrepreneur’s Playbook

For aspiring founders, Jeremy’s insights are deceptively simple: avoid lengthy R&D cycles without immediate sales validation, build strong complementary teams from day one (he built Swirl.GO alone, a hard lesson to learn), and ensure genuine “hair on fire” product-market fit where customers desperately need your solution immediately, even if imperfect.

Perhaps most importantly, Jeremy embodies a form of resilience that is rooted not in blind optimism but systematic problem-solving. “Giving up was never an option, even when SWIRLGO ran out of money multiple times,” he reflects.

Seems like this is what we all need to pivot successfully: a persistence driven by endless curiosity and precise execution, beyond passion and domain expertise. If you are stuck at the crossroads, I hope you’ll find it soon enough.